cGMP-konforme Herstellung

Unsere Wirkstoffproduktion mit modernsten cGMP-zertifizierten Anlagen und hochqualifiziertem Personal entspricht den höchsten Anforderungen der biopharmazeutischen Industrie. Jeder Produktionsprozess ist für unterschiedlichste Anforderungen skalierbar und umsetzbar – für klinische Studien ebenso wie für die Marktversorgung.

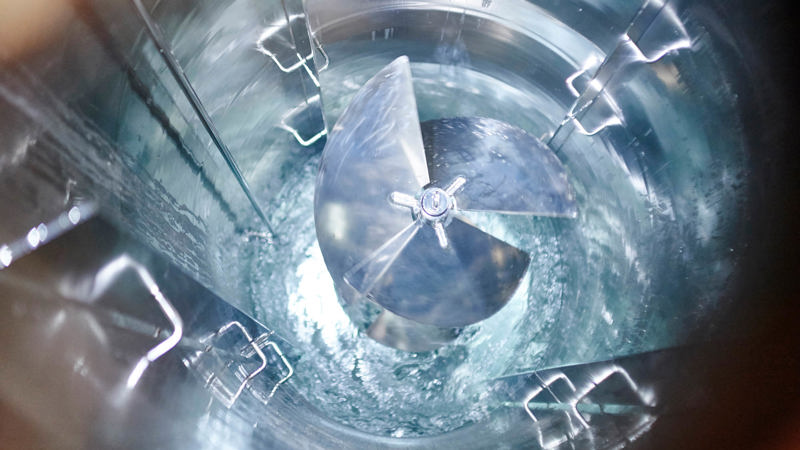

Upstream Processing

Durch einen Best-fit-Produktionsaufbau, Multiproduktanlagen, eine breite Auswahl an Bioreaktoren und Technologien, mehrere Seed-Train- und Upscale-Optionen und hauseigene Supportfunktionen bieten wir Ihnen eine maßgeschneiderte und kosteneffiziente Produktion Ihres Wirkstoffs. Unsere Erfahrung mit einer Vielzahl von rekombinanten Proteinen und innovativen Formaten erlaubt es uns, Ihnen ein breites Portfolio an Kultivierungsmethoden wie Fed-Batch, kontinuierliche und Perfusionsprozesse anzubieten.

Downstream Processing

Die Aufreinigung von Proteinen aus dem Zellkulturüberstand mittels Chromatographie (unter anderem für Affinität, Anion/Kation-Austausch und hydrophobe Interaktion), Filtration, Extraktion, Virusinaktivierung, Virusfiltration und Proteinmodifikation ist ein entscheidender Schritt in der Produktion Ihrer Wirkstoffe. Wir kennen die Anforderungen für verschiedenste therapeutische Proteine wie z.B. monoklonale Antikörper und Fusionsproteine und können für Ihren Wirkstoff die Effizienz und Robustheit der Prozessschritte zuverlässig abbilden, um Ihnen so einen schnellen Marktzugang zu ermöglichen.

Qualitätskontrolle

Unsere Wirkstoffproduktion mit hochmodernen cGMP-Anlagen entspricht den höchsten Qualitätsanforderungen der biopharmazeutischen Industrie. Als Full-Service Anbieter für analytische Testung bieten wir Ihnen folgende Services: umfangreiches Monitoring aller Parameter für die Qualitätskontrolle, die analytische Charakterisierung, die Freigabeprüfung für Wirkstoffe und Fertigarzneimittel sowie die Entwicklung und Qualifizierung von Standard- und produktspezifischen Methoden. Die Qualität unserer Leistung und Ergebnisse sichern wir durch ein umfassendes Qualitätsmanagement und eine präzise und zuverlässige Qualitätskontrolle. Dabei achten wir auf kontinuierliche Überwachung und Anpassung unserer Standards und den Einsatz von modernsten Methoden und Geräten.

Rentschler Biopharma war flexibel bei Projektänderungen an seinen Standorten und die Qualitätsleistung war hervorragend.

— Berater, USA

Flexible Multi-Produkt-Anlagen

Track Record

Kontaktieren Sie unser Business Development Team

Sind Sie daran interessiert, mehr zu erfahren? Wir freuen uns darauf, von Ihnen zu hören.