cGMP Manufacturing

At Rentschler Biopharma we provide cGMP manufacturing at certified, state-of-the-art facilities led by highly skilled scientists and staff to meet the highest standards of the biopharmaceutical industry. From clinical trials to market supply, each active ingredient manufacturing process is scalable and can be tailored to meet your specific requirements.

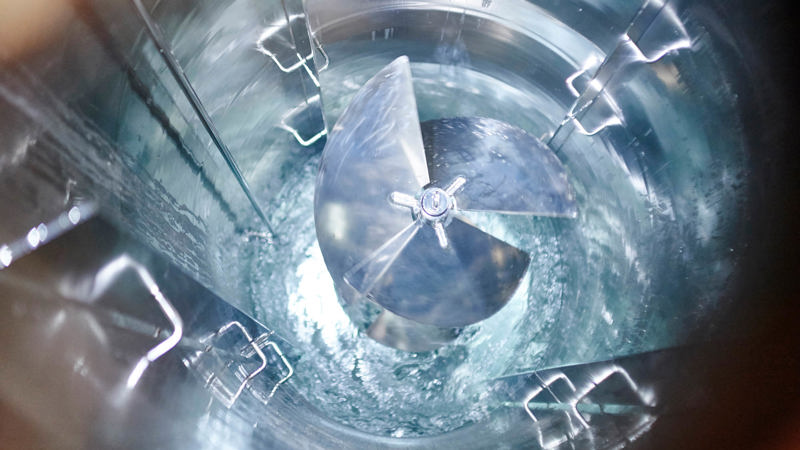

Upstream Processing

With a best-fit production setup, multi-product facilities, a wide range of bioreactors and technologies, multiple seed-train and upscale options and in-house support capabilities, we offer you a customized and cost-efficient production of your active ingredient. Our experience with a variety of recombinant proteins and innovative formats allows us to offer you a broad portfolio of cultivation methods such as fed-batch, continuous and perfusion processes.

Downstream Processing

The purification of proteins from the cell culture supernatant using chromatography (including for affinity, anion/cation exchange and hydrophobic interaction), filtration, extraction, virus inactivation, virus filtration and protein modification is a crucial step in the production of your active ingredients. We know the requirements for a wide range of therapeutic proteins such as monoclonal antibodies and fusion proteins and can reliably map the efficiency and robustness of the process steps for your active ingredient to enable you to access the market quickly.

Quality Control

Our API production with state-of-the-art cGMP facilities meets the highest quality requirements of the biopharmaceutical industry. As a full-service provider for analytical testing, we offer you the following services: comprehensive monitoring of all parameters for quality control, analytical characterization, release testing for APIs and finished dosage forms as well as development and qualification of standard and product-specific methods. We ensure the quality of our services and results through comprehensive quality management and precise and reliable quality control. With meticulous attention to detail, we consistently monitor and adjust our standards and the use of state-of-the-art methods and equipment.

Rentschler Biopharma was flexible with project changes at their sites and the quality performance was excellent.

— Consultant, US

Flexible Multiproduct Plants

Track Record

Get in Touch with our Business Development Team

Are you interested in learning more? We look forward to hearing from you!